- Problem: Sourcing high-quality shoes often feels like a trade-off: either you get top-notch quality with a hefty price tag, or you compromise on craftsmanship to stay within budget. Agitation: You might worry that finding a balance between excellent product and affordable cost is an impossible dream, especially when importing. Solution: But with the right strategies and a deep understanding of the industry, it's absolutely possible to acquire premium footwear at wholesale prices without emptying your wallet.

Sourcing high-quality shoes affordably requires building strong relationships with reliable manufacturers, focusing on efficient supply chain management, and leveraging economies of scale. It involves a meticulous selection process that prioritizes factories with proven quality control, relevant certifications, and transparent production processes, enabling brands to secure superior products without succumbing to exorbitant costs or sacrificing integrity.

In my 25 years at Lucas, our mission has always been about delivering high-quality, fashionable footwear at competitive prices. I’ve seen countless clients navigate the procurement maze. The key is never to compromise on quality, but to be smart about how you achieve it.

Where Can I Buy High-Quality Shoes at Wholesale Prices? Problem: The global market for wholesale shoes is vast and often opaque, making it challenging to know where to begin your search for suppliers who truly offer a combination of quality and competitive pricing. Agitation: It's easy to get lost in a sea of online listings or to feel overwhelmed by the sheer number of potential manufacturers, unsure which ones will deliver the quality you promise to your customers. Solution: To buy high-quality shoes at wholesale prices, you need to navigate established manufacturing hubs, leverage B2B platforms, and build direct relationships with factories known for their consistent quality and fair pricing.

High-quality shoes at wholesale prices are best sourced directly from established manufacturing regions in Asia, particularly China, Vietnam, and India, which offer mature supply chains and specialized production capabilities. Key avenues include attending international trade shows, utilizing reputable B2B online platforms like Alibaba or Made-in-China for initial contact, and, most importantly, conducting thorough due diligence and on-site factory audits to verify quality control and ethical standards before committing to large orders.

When a client comes to Lucas, one of their first questions is often about sources. I always tell them it's not just about finding a factory; it's about finding the right partner for the long term. This means looking beyond the initial quote.

What are the best places to find high-quality wholesale shoe suppliers?

- Established Manufacturing Hubs (Physical Presence or Local Representatives):

- China: Remains the global leader. It offers immense variety, scalable production, and a comprehensive supply chain for all types of shoes. Cities like Dongguan, Wenzhou, and Jinjiang are major footwear manufacturing centers. Lucas is founded in Shaoxing, near Wenzhou, so we are also right in the heart of this. They excel in advanced manufacturing. They also have specialized materials.

- Vietnam: Strong for athletic and outdoor footwear. Many major brands produce there. They have growing expertise. They offer competitive labor costs.

- India: Known for leather footwear. They have skilled craftsmanship. They are growing in other shoe categories too.

- Other emerging hubs: Indonesia, Cambodia, and Pakistan are gaining traction. They often offer lower labor costs. They have developing infrastructure.

- Best approach: Visit these regions if possible. Engage local agents or sourcing companies. This helps with on-the-ground vetting. It also supports communication.

- International Footwear Trade Shows:

- Attending major trade shows is crucial. Examples include Canton Fair (China), Garda Fair (Italy), MICAM (Italy), or FN Platform (USA).

- These shows allow you to meet many suppliers face-to-face. You can inspect samples directly. You can discuss your needs in detail. This builds initial trust.

- Reputable B2B Online Platforms:

- Platforms like Alibaba.com, Made-in-China.com, and Global Sources host thousands of verified suppliers.

- These platforms offer filters for product type, minimum order quantity (MOQ), and certifications. They have supplier ratings and reviews.

- Caution: Always perform due diligence beyond the platform. Request samples. Conduct video factory tours. Verify certifications.

- Networking and Referrals:

- Industry connections are invaluable. Talk to other buyers or brands. They might share their trusted suppliers.

- Join industry forums or associations. These are great places to get recommendations.

- Sourcing Agents/Companies:

- For those without local expertise, a reputable sourcing agent can be a game-changer. They have established networks. They understand local customs and pricing. They can manage quality control.

- Choose carefully: Not all agents are equal. Ensure they are transparent about their fees. Check their references.

Remember, "high-quality" doesn't always mean the most expensive. It means finding a supplier whose production capabilities and quality control align with your brand's standards and your target market's expectations.

Comparative Analysis of Major Shoe Manufacturing Hubs for Wholesale Sourcing

| Manufacturing Hub | Key Strengths | Typical Shoe Types Produced | Considerations for Sourcing |

|---|---|---|---|

| China | Deepest supply chain, vast capacity, advanced tech, wide range. | All types: athletic, fashion, leather, specialized, casual. | Strong quality control potential, but verify carefully. Varies by region/factory. |

| Vietnam | Good for athletic/sneakers, competitive labor costs, growing expertise. | Athletic, casual, outdoor, some formal/fashion. | Strong for major athletic brands. Less diverse supply chain than China. |

| India | Strong in leather footwear, skilled craftsmanship, competitive prices. | Leather dress, casual, sandals, some canvas. | Good for leather; growing in other categories. May have longer lead times. |

| Indonesia | Athletic and casual footwear, good labor pool, established export. | Athletic, casual, some work shoes. | Similar to Vietnam, but may have less infrastructure. |

| Brazil | Strong domestic market, leather footwear, regional exports. | Leather shoes, sandals, some fashion. | Might be higher cost for international export compared to Asia due to logistics. |

| Turkey | Quality leather footwear, fast fashion, good proximity to Europe. | Leather dress, fashion boots, some casual. | Higher labor costs, but strong focus on quality and design. |

| Portugal | High-quality leather footwear, artisanal, ethical production. | Premium leather dress shoes, fashion boots, sustainable options. | Generally higher price point, focuses on niche/luxury. |

What Certifications Should I Look for in a Shoe Factory? Problem: When evaluating potential shoe factories, the sheer number of certifications available can be overwhelming, and it's hard to distinguish which ones genuinely signify quality, ethical production, or environmental responsibility. Agitation: You might worry about partnering with a factory that cuts corners, puts workers at risk, or engages in unsustainable practices, directly impacting your brand's reputation and product quality. Solution: Knowing which key certifications to look for provides a solid baseline guarantee of a factory's commitment to quality management, social accountability, and environmental stewardship, giving you peace of mind and protecting your brand.

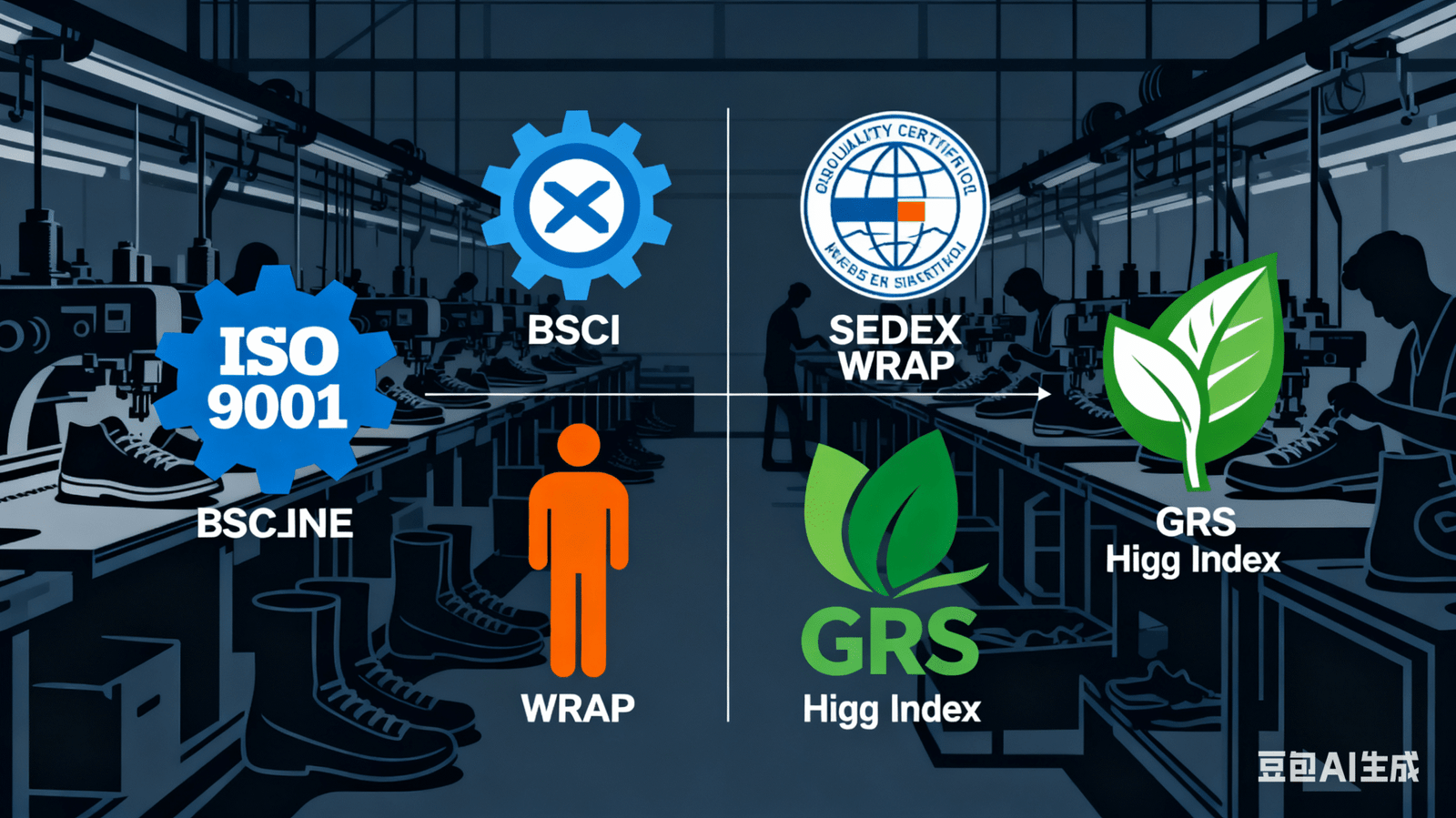

When selecting a shoe factory, look for certifications that demonstrate robust quality management systems like ISO 9001, and social compliance standards such as BSCI (Business Social Compliance Initiative), SEDEX (Supplier Ethical Data Exchange), or WRAP (Worldwide Responsible Accredited Production). Environmental certifications like GRS (Global Recycled Standard) or Higg Index are also crucial for sustainability. These certifications indicate a factory's commitment to consistent quality, ethical labor practices, and environmental responsibility, minimizing risks for your brand.

At Lucas, we understand the importance of integrity. That's why we partner with BSCI and SEDEX-certified factories. We know that these certifications aren't just pieces of paper; they represent a fundamental commitment to responsible manufacturing.

What are the essential certifications for shoe factories?

- Quality Management Systems:

- ISO 9001: This is the most fundamental. It certifies that a factory has a robust Quality Management System (QMS) in place. It means they have procedures for consistent product quality. It focuses on customer satisfaction. It ensures continuous improvement. This is a must-have.

- Social and Ethical Compliance (Worker Rights & Conditions):

- BSCI (Business Social Compliance Initiative): Focuses on improving working conditions in the global supply chain. It covers fair wages, safe working environments, no child labor, and ethical management. Many European brands require this.

- SEDEX (Supplier Ethical Data Exchange): A collaborative platform for sharing ethical supply chain data. SMETA (Sedex Members Ethical Trade Audit) is their audit methodology. It covers labor standards, health and safety, environment, and business ethics. Widely accepted globally.

- WRAP (Worldwide Responsible Accredited Production): Focuses on human rights, health and safety, environmental practices, and customs compliance. Popular in North America.

- SA8000: An auditable certification standard for decent workplaces. It addresses child labor, forced labor, health and safety, and discrimination.

- Why they matter: These certifications indicate a factory adheres to ethical labor practices. They ensure worker well-being. This protects your brand from reputational damage.

- Environmental and Sustainability Certifications:

- GRS (Global Recycled Standard): Certifies products made with recycled content. It verifies the recycled input materials. It tracks them through the supply chain. Important if you are using recycled materials.

- BCI (Better Cotton Initiative): Not directly for shoes, but relevant if your shoes use cotton textiles. Certification ensures cotton is sourced more sustainably. Lucas is a BCI member.

- Higg Index: A suite of tools developed by the Sustainable Apparel Coalition (SAC). It measures environmental and social impacts across the supply chain. While not a direct factory certification, many brands require factories to report their Higg data.

- ISO 14001: Certifies that a factory has an effective Environmental Management System (EMS). It demonstrates a commitment to reducing environmental impact.

- Why they matter: They show a factory's commitment to reducing its environmental footprint. They align with consumer demand for sustainable products.

- Brand-Specific Audits:

- Many large brands (like INDITEX, K-MART, Nike, Adidas) have their own strict compliance programs and audit protocols.

- If a factory has successfully passed audits for these major players, it's a strong indicator of their high standards. And our factories often pass these audits for our customers.

- What to look for: Ask for recent audit reports. Request clarification on any non-conformities found.

Always request copies of current certifications. Also, verify their validity with the issuing body. Certifications establish a baseline, but complementary due diligence, like factory visits and independent quality checks, is also important.

Key Certifications and Their Primary Focus

| Certification/Standard | Primary Focus | Why It's Important for Shoe Sourcing |

|---|---|---|

| ISO 9001 | Quality Management System: Ensures consistent quality, customer satisfaction. | Fundamental: Guarantees a factory has systematic processes for quality control. |

| BSCI Audit | Social Compliance: Fair labor practices, safe working conditions, no child labor. | Ethical Sourcing: Protects brand reputation, ensures worker well-being. |

| SEDEX/SMETA Audit | Ethical Trade: Broader social and environmental responsibility, transparency. | Comprehensive Due Diligence: Covers labor, health, environment, business ethics. |

| WRAP | Global Social Compliance: Focus on lawful, humane, and ethical manufacturing. | US Market Relevance: Widely recognized, especially for North American brands. |

| GRS | Recycled Content Verification: Traces recycled materials through supply chain. | Sustainability Focus: Essential for brands using recycled components. |

| BCI Membership | Sustainable Cotton Sourcing: Promotes better cotton farming practices. | Material Footprint: Relevant if your shoes include cotton textiles. |

| ISO 14001 | Environmental Management System: Minimizing environmental impact. | Eco-Conscious Sourcing: Demonstrates commitment to environmental responsibility. |

Should I Work with Trading Companies or Direct Factories? Problem: When you're new to international sourcing, deciding whether to partner with a trading company or go straight to a direct factory can be confusing. Each option presents its own set of advantages and disadvantages. Agitation: You might worry about hidden costs, communication breakdowns, or a lack of control over your production if you make the wrong choice, potentially jeopardizing your order and reputation. Solution: Understanding the distinct roles and benefits of trading companies versus direct factories will empower you to choose the sourcing strategy that best aligns with your brand's size, experience, and specific needs, ensuring a smooth and successful production process.

The choice between a trading company and a direct factory depends on your business's scale, experience, and control preferences. Trading companies offer convenience, diversified product access, and often better communication for smaller or less experienced buyers. Direct factories, conversely, typically provide lower costs, greater control over production and quality, and foster long-term partnerships for larger, more established brands. Evaluating your specific needs is crucial for making the optimal sourcing decision.

At Lucas, we operate as a mix—we have our own factory setups and also leverage a network of certified partner factories. This allows us to serve diverse client needs effectively. But the core decision for our clients remains whether to directly engage a factory or use an intermediary.

Comparing Trading Companies vs. Direct Factories:

- Working with Trading Companies:

- Pros:

- Convenience and Simplicity: They act as an intermediary, handling communication, logistics, and often finding multiple suppliers for different products.

- Lower MOQs (Minimum Order Quantities): They can consolidate orders from various clients, allowing you to buy smaller quantities.

- Diversified Product Range: One trading company can often source a wide variety of shoes or other goods, simplifying your supplier management.

- Better Communication: They often have multilingual staff. They are experienced in bridging cultural and communication gaps.

- Problem Resolution: They can often help mediate issues with factories. They leverage their existing relationships.

- Cons:

- Higher Costs: They add a margin for their services. This means higher unit costs for you.

- Less Control: You have less direct oversight of the production process. You might not know the actual factory making your shoes.

- Potential for Miscommunication: Information can get lost or distorted. It goes through an extra layer.

- Limited Transparency: You might not get full transparency on factory conditions or exact production steps.

- Pros:

- Working with Direct Factories:

- Pros:

- Lower Costs: You cut out the middleman's markup. This typically results in better pricing.

- Greater Control and Transparency: You can directly communicate your specifications. You can monitor production progress. You can conduct quality checks on-site.

- Long-Term Relationships: Building a direct relationship fosters trust and partnership. This can lead to better cooperation. It allows for product development.

- Direct Feedback and Customization: You can provide direct feedback. You can work on customizations more easily.

- Better Quality Assurance: You can implement your own QC protocols. You can verify the factory's quality directly.

- Cons:

- Higher MOQs: Factories prefer larger orders for efficiency. This might be a barrier for smaller businesses.

- More Complex Communication: You deal directly with the factory. This can involve language barriers. It might also involve cultural differences.

- More Responsibility: You manage all aspects of sourcing. This includes quality control, logistics, and problem-solving.

- Limited Product Range: A factory usually specializes in a certain type of shoe. You might need multiple factories for different products.

- Pros:

Which to Choose?

- For smaller or new businesses: A reputable trading company might be a safer starting point. They offer guidance and flexibility. They simplify the process initially.

- For established businesses with larger orders: Going direct to a factory is often more cost-effective. It provides better control and fosters deeper partnerships.

Ultimately, build trust with either. Conduct thorough due diligence. Ensure clarity in all communications.

Trade-Offs: Trading Company vs. Direct Factory

| Feature | Trading Company Advantage | Direct Factory Advantage | Implication for Shoe Sourcing Decision |

|---|---|---|---|

| Cost Per Pair | Usually higher (includes middleman margin) | Lower (no middleman markup) | Decision based on budget & volume: Higher volume warrants direct. |

| Minimum Order Quantity (MOQ) | Often lower (aggregates orders) | Higher (prefers large production runs) | Decision based on business scale: Small brands start with TCs. |

| Product Variety | Very broad (can source from many factories) | Specialized (focuses on specific shoe types) | Decision based on product range: Diverse SKU needs --> TC. |

| Communication & Ease | Easier (often multilingual, handles logistics) | More challenging (direct communication, potential language/cultural barriers) | Decision based on experience & resources: Newer buyers prefer TC. |

| Control & Transparency | Less (limited visibility into actual production) | High (direct oversight, on-site QC possible) | Decision based on quality/process control preference: High control --> DF. |

| Relationship Building | Indirect (relationship with TC, not factory) | Direct (fosters strong, long-term partnerships) | Decision based on long-term strategy: Strategic partnership --> DF. |

| Problem Resolution | TC often handles, leverages their existing factory relationships | Direct negotiation with factory, potentially more complex | Decision based on comfort with direct negotiation. |

Sourcing high-quality shoes affordably requires strategic choices. Prioritize established manufacturing hubs and reputable B2B platforms. Look for factories with ISO 9001, BSCI, or SEDEX certifications for quality and ethics. Finally, decide between trading companies for convenience or direct factories for greater control, based on your business size and needs. This careful approach ensures both quality and cost efficiency.