Problem: Our old sneakers often end up in landfills, taking decades to decompose and contributing to growing waste piles. Agitation: It's hard to imagine what good can come from that old, worn-out pair of athletic shoes, seemingly destined for oblivion. Solution: But what if those beloved old kicks could get a second life, transforming into vibrant playgrounds and athletic tracks, not only diverting waste but creating vital community spaces for children and athletes alike?

Old sneakers are being turned into playgrounds and tracks through specialized recycling programs that collect, sort, and then meticulously shred the shoes into their constituent rubber, foam, and fabric components. These materials are then processed, separated, and re-engineered into safe, resilient, and shock-absorbing surfacing granules, which are subsequently laid down to create colorful and durable play areas and running tracks, giving athletic footwear a remarkable new purpose.

How Widespread Are Sneaker-to-Playground Programs Globally? Problem: You might hear about a cool recycling initiative where old sneakers become new playgrounds, but wonder if it's just a one-off project or a genuinely global movement. Agitation: Is this a widespread solution making a real difference in communities worldwide, or is it limited to a few experimental programs in a handful of places? Solution: Let's assess the global reach and adoption of sneaker-to-playground and track recycling programs, revealing their current spread and future potential.

Sneaker-to-playground programs are gaining traction globally, led by major athletic brands like Nike (with its "Nike Grind" program) and increasingly supported by local governments, non-profits, and educational institutions across North America, Europe, and parts of Asia. While not yet ubiquitous, their presence is expanding, demonstrating a growing commitment to circular economy principles and turning shoe waste into valuable community infrastructure, though large-scale adoption still faces logistical and economic hurdles.

What are the main drivers of these programs?

- Major Athletic Brands: Companies like Nike have been pioneers. Their "Nike Grind" program, launched in 1990, collects athletic footwear and excess manufacturing material. They then grind it down into materials for various applications. These applications include playgrounds and tracks. Other brands are following suit.

- Government Initiatives: Some city or regional governments are recognizing the environmental benefits. They are supporting collection points and funding for recycled material playgrounds. They often partner with recycling companies.

- Non-Profit Organizations: Environmental groups. Community development organizations. These groups often facilitate collection drives. They advocate for using recycled materials in public spaces.

- Specialized Recycling Companies: Companies focusing on textile and rubber recycling are crucial. They develop the technology to process complex materials like shoes. They turn them into usable granules.

Where are these programs most active?

- North America: The United States and Canada have a significant number of these programs. Nike Grind facilities are present. Many schools and municipalities use recycled tire and shoe materials for playgrounds.

- Europe: Several European countries have strong recycling infrastructures. They are increasingly adopting shoe recycling for public amenities. Germany, the UK, and Scandinavian countries are often at the forefront.

- Asia: Countries like Japan and South Korea have advanced recycling economies. They are seeing increased activity. China, with its vast manufacturing base, also has growing initiatives.

- Australia and New Zealand: These countries are also implementing programs. They are focusing on reducing landfill waste.

What are the challenges to global spread?

| Challenge Type | Description | Impact on Global Spread |

|---|---|---|

| Collection Logistics | Setting up accessible and efficient collection points for old shoes is complex. It requires public awareness and participation. | Less developed countries may lack the infrastructure, limiting the volume of recyclable shoes. |

| Processing Technology | Disassembling and processing shoes requires specialized machinery. This machinery separates rubber, foam, and fabric. | High initial investment for recycling plants makes it less viable in regions with limited capital. |

| Cost vs. Virgin Materials | Recycled materials can sometimes be more expensive than new, virgin materials (especially in regions with cheap labor/resources). | Decisions to use recycled content are often based on grants or environmental mandates rather than pure economics. |

| Awareness & Participation | Many consumers are unaware that their shoes can be recycled this way, or how to do it. | Low collection rates mean less material available for conversion, slowing the growth of programs. |

| Quality Control | Ensuring the consistency and quality of recycled granules for safety standards in playgrounds is paramount. | Stringent regulatory requirements can make it harder for new recyclers to enter the market. |

While challenges exist, the trend is positive. More brands are looking for end-of-life solutions. More communities are seeking sustainable infrastructure. The demand for recycled materials like those from shoes will likely continue to grow. This growth will push these programs to become even more widespread.

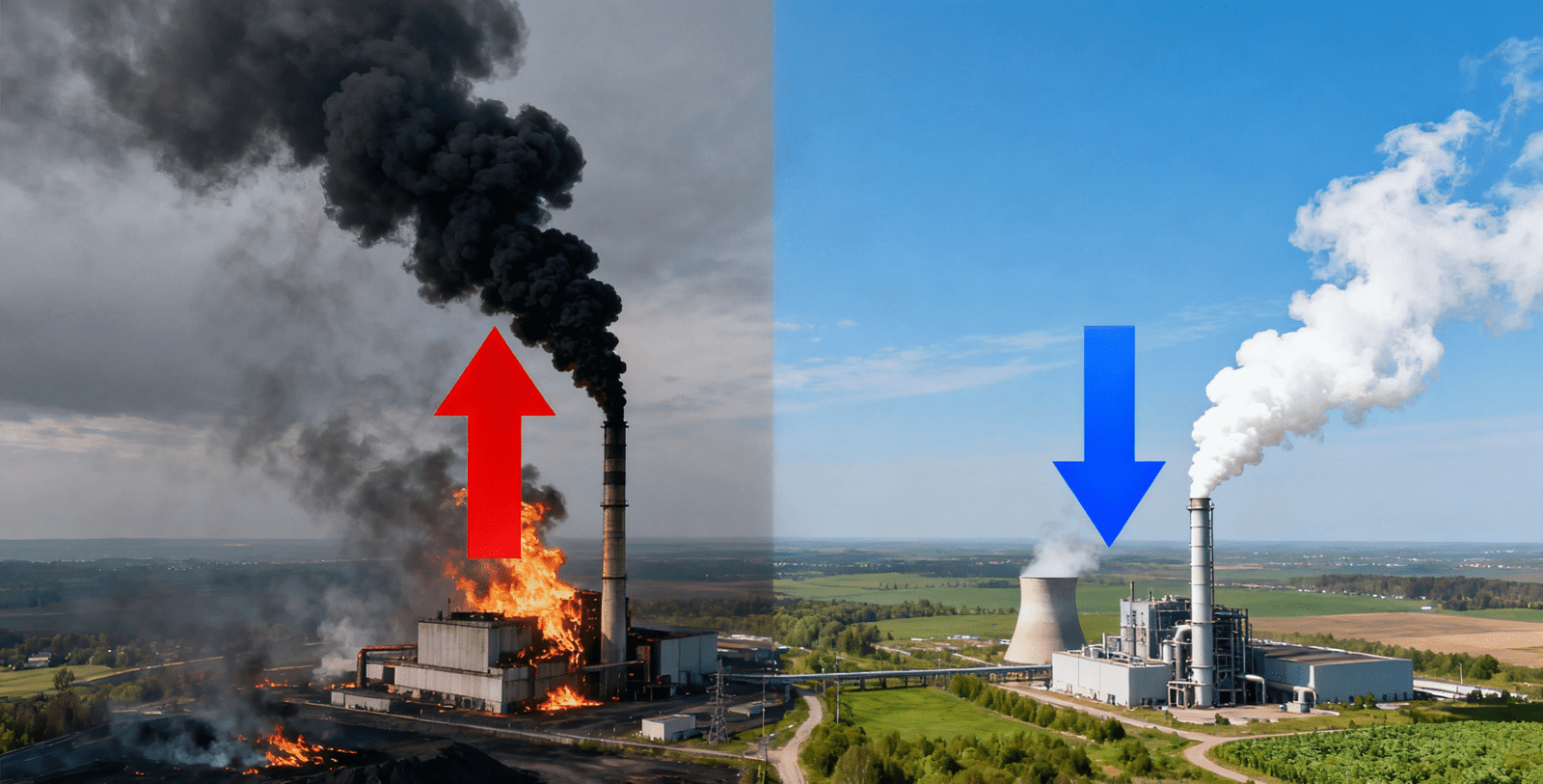

What Environmental Impact Do These Recycling Initiatives Have? Problem: Sending old shoes to landfills feels wrong, but what's the actual environmental benefit of diverting them into playgrounds and tracks? Agitation: Beyond simply "reducing waste," what are the tangible positive effects of these sneaker recycling initiatives on our planet? Solution: Let's delve into the significant environmental impact of transforming old sneakers into new community assets, exploring how it conserves resources, reduces pollution, and lessens carbon footprints.

These sneaker recycling initiatives have a substantial positive environmental impact by diverting millions of pounds of waste from landfills, thereby reducing soil and water pollution from decomposing materials and mitigating greenhouse gas emissions associated with incineration. By repurposing existing materials, they significantly conserve natural resources and energy that would otherwise be consumed in producing new playground and track surfaces, embodying a truly circular economy approach.

What are the direct environmental benefits?

- Reduction in Landfill Waste: This is the most immediate and obvious impact. Shoes, especially athletic ones, are made from complex materials like rubber, foam, textiles, and plastics. Many of these materials are not biodegradable. They can sit in landfills for decades or even centuries. Diverting them significantly reduces landfill volume. It saves valuable land.

- Conservation of Natural Resources:

- Rubber: Tires and shoe soles rely on rubber. This either comes from trees (natural rubber) or petroleum (synthetic rubber). Recycling shoe rubber reduces the need to harvest more trees. It reduces reliance on fossil fuels.

- Plastics and Textiles: Recycling these components lessens the demand for virgin plastics and new textile production. This saves raw materials. It saves the energy used in their extraction and processing.

- Reduced Pollution:

- Soil and Water Contamination: As shoes slowly break down in landfills, they can leach chemicals and microplastics into the soil and groundwater. Recycling prevents this.

- Air Pollution (from Incineration): Burning shoes to dispose of them releases harmful greenhouse gases and toxic pollutants into the atmosphere. Recycling avoids this.

- Lower Energy Consumption: Producing materials from recycled content often requires less energy than producing them from virgin raw materials. For example, recycling plastic can use significantly less energy than making new plastic.

- Reduced Carbon Footprint: By avoiding new material production and landfilling/incineration, these programs substantially lower the overall carbon emissions associated with footwear. This contributes to climate change mitigation.

What are the indirect environmental benefits?

- Promoting a Circular Economy: These initiatives are a prime example of a circular economy. Products are designed to be reused or recycled. This keeps materials in use for as long as possible. It minimizes waste. It reduces resource consumption.

- Raising Awareness: Visible projects like playgrounds made from recycled shoes educate the public. They show the potential of recycling. They encourage more conscious consumption. They spark interest in sustainable practices.

- Creating Green Jobs: The collection, sorting, processing, and installation of recycled materials create new employment opportunities in the green sector.

| Environmental Category | Impact Description | Specific Metrics/Examples |

|---|---|---|

| Waste Reduction | Diverts non-biodegradable, complex materials from landfills. | A single running track can use thousands of pairs of shoes. |

| Resource Conservation | Reduces demand for new rubber, plastic, and textile production. | Saves petroleum (for synthetic rubber/plastics) and tree resources (for natural rubber). |

| Pollution Control | Prevents leaching of chemicals and microplastics into soil/water. Avoids air pollution from incineration. | Less toxic runoff, cleaner air from reduced burning of waste. |

| Energy Savings | Manufacturing with recycled materials typically consumes less energy. | Up to 75% energy saved compared to virgin material production for some plastics. |

| Carbon Footprint | Lowers greenhouse gas emissions by avoiding new production and landfill decomposition. | Contributes to climate change mitigation. |

The environmental impact is significant. It's a tangible way to clean up the planet while simultaneously creating valuable public spaces. This makes it a win-win for both the environment and communities.

How Much Waste Can Sneaker Recycling Programs Prevent Each Year? Problem: While we know sneaker recycling is good, it's hard to grasp the scale of its impact without concrete numbers. Agitation: Is it preventing a few hundred shoes from going to landfills, or are we talking about millions of pounds of waste diverted annually? Solution: Let's investigate the potential and actual quantities of waste that sneaker recycling programs can prevent from entering landfills each year, providing a clearer measure of their environmental contribution.

Sneaker recycling programs, particularly those led by major brands, can prevent millions of pounds of footwear waste from ending up in landfills annually. For instance, Nike's Grind program alone has repurposed over 30 million pairs of shoes since its inception, and currently processes millions of pounds of material each year. While exact figures fluctuate, the collective efforts of various programs globally are diverting substantial quantities of complex, slow-decomposing shoe components, contributing significantly to waste reduction on a large scale.

What are the reported figures from major programs?

- Nike Grind: This is by far the largest and most well-documented program. Since its beginning in 1990, Nike Grind has repurposed over 30 million pairs of shoes and more than 100 million pounds of factory scrap material. Each year, they continue to process millions of pounds of athletic footwear and factory materials. This diverts them from landfills. They then transform them into materials used in sports surfaces, playgrounds, and other products.

- Lululemon: While not exclusively sneakers, Lululemon's "Like New" program aims to collect used apparel. Their goal is to divert 10 million pounds of product waste by 2025. This shows the growing commitment from major apparel players.

- Smaller and Local Programs: While individual smaller programs or local initiatives might only divert thousands or tens of thousands of shoes annually, their collective impact is significant. For example, a single medium-sized playground can utilize materials from hundreds, if not thousands, of pairs of shoes.

What factors affect the amount of waste prevented?

- Collection Infrastructure: The easier it is for consumers to drop off shoes, the more shoes will be collected. The number of drop-off points, mail-back programs, and community collection events directly impacts volume.

- Consumer Awareness and Participation: If people don't know about the programs or don't feel motivated to participate, fewer shoes will enter the recycling stream. Marketing and education are key.

- Processing Capacity: The number and size of dedicated shoe recycling facilities determine how much material can actually be processed and repurposed.

- Demand for Recycled Material: If there's high demand from construction companies, municipalities, and other manufacturers for recycled rubber and plastic granules, it creates a viable market for the output of these recycling programs.

| Metric | Scale of Impact | Explanation |

|---|---|---|

| Pairs Diverted | Millions of pairs annually (global, major programs) | Nike Grind alone has processed over 30 million pairs since 1990, and continues to process millions yearly. |

| Weight of Material | Millions of pounds per year | This accounts for all components: rubber soles, foam midsoles, fabric uppers, etc. |

| Landfill Volume Saved | Equivalent to thousands of cubic yards | Preventing dense, slow-decomposing materials from occupying precious landfill space. |

| Energy Saved | Significant megajoules/gigajoules | Less energy used to process recycled materials than to produce new ones. Reduces reliance on fossil fuels. |

While a precise global figure is challenging to obtain—given the many disparate programs—it's clear that these initiatives are making a substantial dent in footwear waste. They represent one of the most effective solutions for a product that is notoriously difficult to recycle due to its multi-material construction. Lucas is watching these developments closely. We are considering how we can integrate better end-of-life solutions into our own product designs.

Are Recycled Sneaker Surfaces Safe for Children? Problem: It's wonderful to reuse old materials, but concerns naturally rise when it comes to children's safety on playgrounds made from recycled products. Agitation: Are surfaces made from old sneakers truly safe, free from harmful chemicals, allergens, or physical hazards that might originate from their previous life? Solution: Let's address the safety aspects of playgrounds and tracks made from recycled sneaker materials, assuring that rigorous testing and standards are in place to protect children and athletes.

Yes, recycled sneaker surfaces are safe for children and athletes, undergoing stringent processing and testing to meet established safety standards for playgrounds and athletic tracks. The materials are meticulously cleaned, contaminants removed, and the resulting granules are engineered to be non-toxic, lead-free, and provide excellent shock absorption, significantly reducing the risk of injuries from falls. Reputable programs like Nike Grind adhere to strict health and environmental guidelines, ensuring the final product meets or exceeds industry safety regulations.

What makes these surfaces safe?

- Rigorous Processing and Contaminant Removal:

- Thorough Cleaning: Collected shoes are extensively cleaned. This removes dirt, debris, and potential biological contaminants.

- Material Separation: The shoes are broken down into their core components: rubber (outsoles), foam (midsoles), and fabric (uppers). These materials are then individually processed.

- Impurities Extraction: Advanced machinery extracts non-recyclable parts and small impurities. This ensures the purity of the materials used in the final surface.

- Non-Toxic and Lead-Free Standards:

- Testing for Chemicals: The recycled granules undergo strict testing. This looks for heavy metals (like lead and cadmium), phthalates, and other potentially harmful chemicals. Manufacturers ensure that the materials meet or exceed safety regulations set by bodies like the U.S. Consumer Product Safety Commission (CPSC) and ASTM International standards for playground surfacing.

- Volatile Organic Compounds (VOCs): Emissions of VOCs (which can cause respiratory irritation) are also typically monitored and kept within safe limits.

- Shock Absorption and Fall Protection:

- Engineered Properties: The rubber and foam granules from shoes are ideal for creating impact-absorbing surfaces. They are specifically designed and tested to cushion falls from various heights, significantly reducing the risk of head injuries or serious trauma.

- Critical Fall Height (CFH) Certification: Playgrounds are certified based on their CFH. This is the maximum height from which a child can fall onto the surface without sustaining a life-threatening head injury. Recycled shoe materials can achieve high CFH ratings.

- Durability and Stability:

- Weather Resistance: The synthetic materials are inherently weather-resistant. They do not degrade significantly when exposed to UV light, moisture, or temperature fluctuations. This maintains their integrity and safety over time.

- Slip Resistance: The granules are often designed to provide good traction, reducing slips and falls.

Are there any concerns or ongoing efforts?

- Microplastic Shedding: A general concern with any synthetic surface is the potential for microplastic shedding. While these surfaces are designed to be stable, ongoing research is exploring long-term exposure. However, studies so far generally indicate that the benefits outweigh potential risks in playground settings.

- Installation and Maintenance: Proper installation by certified professionals is crucial. Regular maintenance (e.g., cleaning, infill top-ups) ensures the surface continues to perform safely throughout its lifespan.

In sum, the use of recycled sneaker materials in playgrounds and tracks is not a haphazard process. It's a highly controlled and regulated one. The leading programs and material suppliers invest heavily in research, development, and stringent testing. They ensure that these sustainable surfaces provide a safe and effective environment for recreational activities. As an industry veteran, I am confident that these programs prioritize safety, making them a truly beneficial reuse of materials.

Old sneakers are being transformed into playgrounds and tracks through sophisticated recycling, diverting millions of pounds of waste from landfills, conserving resources, and significantly reducing pollution. This global movement, spearheaded by brands like Nike Grind, not only makes a tangible environmental impact but also creates safe, durable, and highly tested surfaces for communities, demonstrating a powerful circular economy solution for footwear waste.