Problem: For years, 3D printing has been a buzzword in manufacturing, promising revolutionary changes, yet mass-produced 3D-printed shoes like those seen in sci-fi movies still feel far off. Agitation: You might wonder if this technology is just a niche novelty for high-end prototypes or if it truly has the potential to transform the footwear industry for everyday consumers. Solution: While not a complete replacement for traditional methods yet, advancements in materials, speed, and design are increasingly pushing 3D-printed shoes beyond the conceptual phase, making them more viable for specialized markets and hinting at future mass adoption.

3D printing in footwear is rapidly evolving, moving beyond prototyping to create functional components like midsoles and outsoles, primarily for customized, performance, and limited-edition shoes. While it’s not fully replacing traditional mass manufacturing due to cost and speed limitations for entire shoes, the technology offers unparalleled design freedom, personalized fit, and material efficiency, making it increasingly relevant for specific market segments and driving future innovation towards wider adoption.

In my over two decades at Lucas, I've seen countless "next big things." 3D printing has consistently been on our radar, not as a complete overhaul, but as a powerful tool to enhance design, accelerate prototyping, and even revolutionize certain production segments.

Is 3D Printing Replacing Traditional Shoe Manufacturing? Problem: The idea of a machine printing out a shoe on demand sounds futuristic and efficient, leading some to believe that traditional shoe factories with their assembly lines and skilled labor are nearing obsolescence. Agitation: If 3D printing is truly the future, you might worry about the job market in traditional manufacturing or whether this shift will render your existing production expertise obsolete, causing uncertainty about the industry's direction. Solution: No, 3D printing is not replacing traditional shoe manufacturing entirely, but rather augmenting it by offering unique capabilities for specific components, customization, and prototyping, thriving alongside conventional methods rather than rendering them obsolete.

3D printing is not currently replacing traditional shoe manufacturing for mass market production due to higher costs, slower speeds for full shoe production, and material limitations. Instead, it serves as a powerful complementary technology, primarily used for rapid prototyping, creating customized midsoles and intricate components (like Adidas' 4D soles), and producing limited edition or high-performance athletic footwear. It excels in design flexibility and personalization, areas where traditional methods are less efficient, but conventional manufacturing remains dominant for large-scale, cost-effective shoe production.

At Lucas, we view 3D printing as an incredible design enhancement tool. It allows us to innovate faster in the design phase and create bespoke elements that would be impossible with traditional molds, rather than seeing it as a complete replacement for our assembly lines.

3D Printing's Role vs. Traditional Manufacturing

- Complementary, Not Replacement (Currently):

- 3D printing is largely a complementary technology. It fills gaps where traditional manufacturing falls short.

- It excels in complex geometries. It allows for intricate lattice structures. These are impossible with conventional molding.

- This is seen in Adidas' 4D midsoles. Nike has also used 3D printing for specific components in performance shoes.

- Speed and Scale:

- Traditional Manufacturing: Unbeatable for mass production speed once molds are made. High volumes are produced quickly and cost-effectively per unit. Factories can churn out thousands of pairs daily.

- 3D Printing: Still relatively slower. Printing an entire shoe, even just a midsole, can take hours. This makes it impractical for millions of units. Multi-material printing for full shoes is nascent.

- Cost:

- Traditional Manufacturing: High upfront cost for tooling (molds). Low per-unit cost for mass production. Very economical at scale.

- 3D Printing: No tooling costs. Setup is quick. But per-unit cost remains high due to material cost and print time.

- Material Limitations:

- Traditional Manufacturing: Very wide range of rubber, foam, textile, and plastic materials. Established performance characteristics.

- 3D Printing: Limited to specific polymer resins or powders. While materials are improving, they do not yet match the full spectrum or cost-effectiveness of traditional footwear materials.

- Primary Applications of 3D Printing in Footwear:

- Rapid Prototyping: Designers can quickly test new sole designs or shoe components. Iterations are fast and cheap.

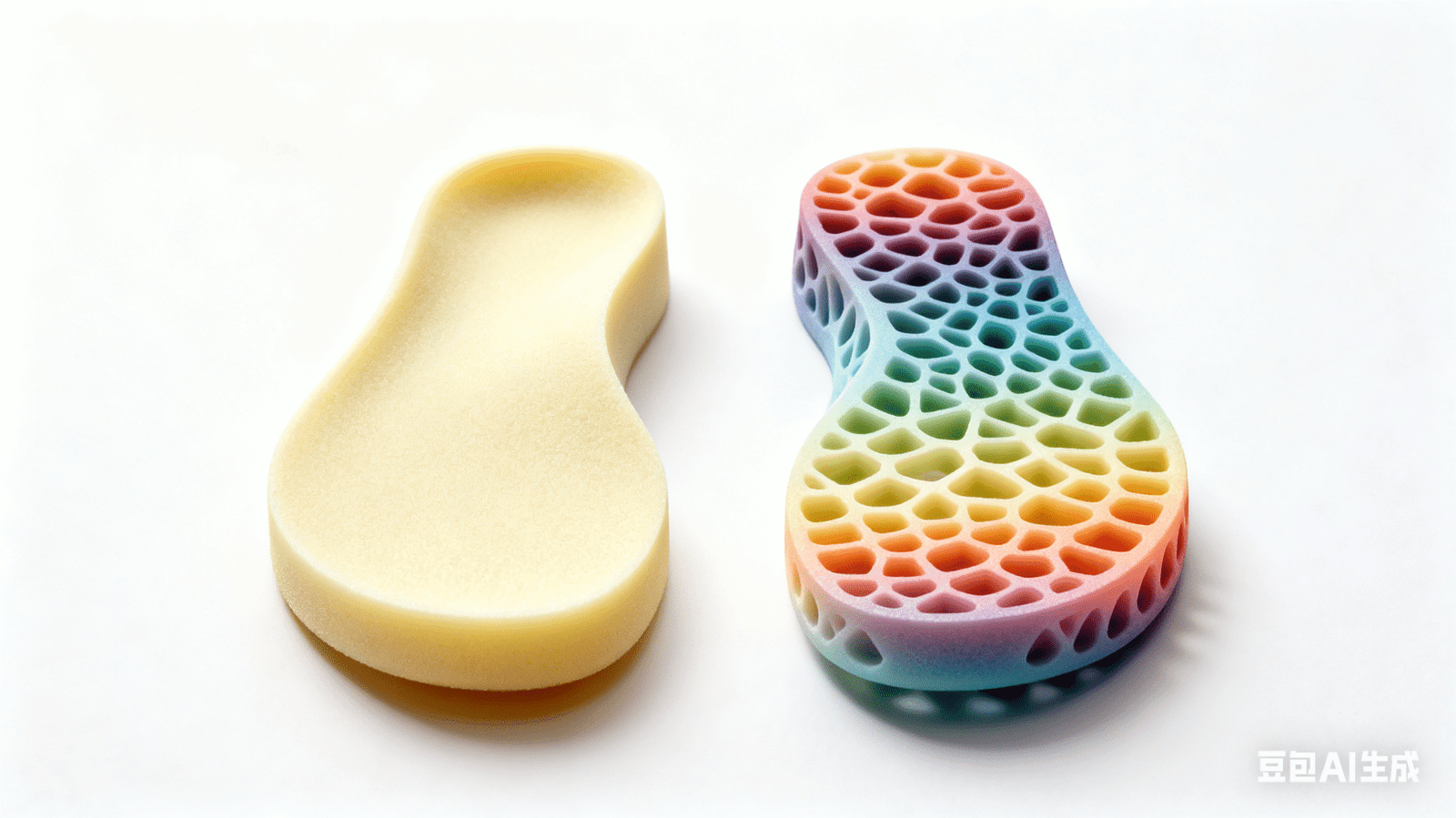

- Customization and Personalization: Orthotics, insoles, or midsoles precisely tailored to an individual's foot data or gait. This is a huge advantage for performance or medical footwear.

- Complex Geometries: Creating intricate lattice structures for cushioning or support. These are optimized for weight and performance.

- Limited Edition and Premium Footwear: For high-value, low-volume products where design uniqueness justifies the cost.

So, while your local shoe factory producing thousands of pairs daily isn't going anywhere, 3D printing is steadily carving out its essential niche in product development, customization, and high-performance segments.

Traditional vs. 3D Printing (Currently)

| Feature | Traditional Manufacturing (Mass Production) | 3D Printing (Additive Manufacturing) |

|---|---|---|

| Primary Use | High-volume, cost-effective production of standardized designs. | Prototyping, customization, complex geometries, limited editions. |

| Speed (per unit) | Very fast once setup (seconds/minutes per component at scale). | Relatively slow (hours per component/shoe). |

| Cost (per unit) | Low, especially at high volumes (after initial tooling investment). | High (material cost + machine time), even for single units. |

| Design Flexibility | Limited by mold constraints, harder for intricate or custom shapes. | Extremely High: Can create highly complex, intricate, and customized designs. |

| Material Range | Very broad (rubber, EVA, TPU, leather, fabric, etc.), established properties. | Limited to specific printable polymers (though expanding rapidly). |

| Tooling/Molds | Required (high upfront cost). | Not required (tool-less manufacturing). |

| Waste | Can have significant material waste (subtractive processes). | Minimal material waste (additive process). |

| Personalization | Difficult and expensive for tailored fits. | Highly efficient for mass customization/individual fit. |

Are 3D-Printed Shoes Durable Enough for Everyday Wear? Problem: When you hear "3D printed," you might picture fragile plastic prototypes, leading to doubts about whether such footwear could withstand the rigors of daily walking, running, and general wear and tear. Agitation: You might worry that these innovative shoes prioritize novelty over longevity, meaning they’ll quickly fall apart and negate any environmental or performance benefits with a short lifespan. Solution: Driven by rapid advancements in material science and printing technology, modern 3D-printed shoe components are engineered for durability, often matching or even exceeding the performance and lifespan of conventionally manufactured parts, making them increasingly viable for everyday wear.

Yes, 3D-printed shoe components, especially midsoles made from advanced polymer resins, are indeed durable enough for everyday wear, often offering comparable or superior performance to traditional foam or rubber. Companies like Adidas with their 4D line have demonstrated significant resilience and cushioning properties over extended use. While full 3D-printed shoes are less common, the printed performance components are designed and rigorously tested to withstand the forces and abrasion of regular activity, ensuring longevity for the lifespan of the shoe.

At Lucas, when we evaluate new materials, durability is paramount. A shoe, no matter how innovative, must last. We've seen firsthand how far 3D print materials have come in terms of resilience and performance, making them a serious consideration for functional footwear.

Factors Affecting Durability and Performance

- Material Science Advancements:

- Early 3D printing materials were brittle. Modern materials like specialized thermoplastic polyurethanes (TPUs) and resins are highly flexible, resilient, and durable.

- Companies like Carbon (who partner with Adidas for 4D) use proprietary liquid resins. These resins cure into elastomeric lattices. These lattices offer excellent energy return and abrasion resistance.

- Lattice Structures and Design Optimization:

- The unique ability of 3D printing to create intricate lattice structures is key. These structures are optimized for performance.

- They can be varied in density and stiffness. This provides cushioning where needed. They offer support where required. This design freedom allows for targeted durability.

- This makes the midsole functional and long-lasting. It also improves impact absorption.

- Rigorous Testing:

- Major brands like Adidas conduct extensive lab and wear testing. They ensure 3D-printed components meet performance standards. This includes durability, cushioning, and responsiveness.

- These components are subjected to similar tests as their traditionally manufactured counterparts.

- Targeted Application:

- Often, only specific parts of the shoe are 3D printed. The midsole is the most common example. This component is designed for resilience.

- The rest of the shoe (upper, outsole) is made with traditional, known-durable materials. This ensures overall longevity.

- Performance Comparison:

- Adidas' 4D midsoles, for example, are designed to offer long-term cushioning. They resist compression set better than some traditional EVA foams. This means they maintain their springiness over time.

- The open cellular structures can also facilitate airflow. This can improve thermal regulation.

So, while the term "3D printed" might still evoke fragility for some, the reality in high-performance footwear is vastly different. These materials are specifically engineered to withstand daily wear and tear. They deliver robust performance.

Durability Comparison: 3D-Printed vs. Traditional Midsoles

| Aspect | Traditional Midsoles (e.g., EVA, PU foam) | 3D-Printed Midsoles (e.g., Lattice structures from resins/TPUs) |

|---|---|---|

| Material Basis | Petroleum-based foams (EVA, PU) | Advanced resins, photopolymers, or thermoplastic polyurethanes (TPU). |

| Cushioning | Good initial cushioning, can "pack out" over time. | Excellent, highly responsive, geometry-tuned for specific needs, often retains properties longer. |

| Compression Set | Can experience permanent deformation over prolonged use. | Engineered to resist compression set, maintaining springiness and shape. |

| Weight | Varies by foam type; can be lightweight. | Can be extremely lightweight due to open lattice structures and optimized material usage. |

| Abrasion | Good, depending on the foam and outsole material. | Good, especially for outer layers or if combined with durable rubber outsoles. |

| Flexibility | Good, can be engineered for specific flex zones. | Excellent, can be highly tuned in specific directions via lattice design. |

| Lifespan | Well-established, typically lasts 300-500 miles for running shoes. | Comparable to or potentially longer, as material properties are often maintained better. |

| Cost | Lower per unit for mass production. | Higher per unit due to material cost and print time. |

What Are the Limitations of 3D-Printed Footwear? Problem: Despite the exciting potential of 3D printing in footwear, it's not without its drawbacks, and understanding these limitations is crucial for a realistic assessment of its current market readiness. Agitation: Without knowing the boundaries of this technology, you might have unrealistic expectations regarding its affordability, production speed, or material versatility, leading to disappointment or misinformed investment decisions. Solution: Key limitations of 3D-printed footwear include high production costs, slow manufacturing speeds for entire shoes, limited material variety compared to traditional methods, and challenges in multi-material printing for a fully integrated product.

The primary limitations of 3D-printed footwear include its current high production cost per unit, making it unsuitable for mass market pricing. Manufacturing speed is another hurdle, as printing an entire shoe or even complex components still takes significant time. Material selection is narrower compared to traditional methods, and achieving multi-material integration for a cohesive, functional shoe remains challenging. These factors currently restrict its widespread adoption, largely confining it to premium, customized, or prototype applications.

At Lucas, innovation is key, but so is practicality. While we're excited about 3D printing's potential, we're keenly aware of its current limitations. Understanding these helps us guide our R&D investments and set realistic expectations for our clients.

Key Limitations of 3D-Printed Footwear

- High Production Cost:

- Material Costs: The specialized polymer resins and powders used in 3D printing are significantly more expensive per kilogram than traditional materials like EVA foam or rubber.

- Machine Costs: Industrial 3D printers are a substantial capital investment.

- Post-Processing: Many 3D-printed parts require post-processing steps (cleaning, curing, finishing), adding to labor and time costs.

- Result: This leads to a high per-unit cost. This makes 3D-printed shoes inaccessible for mass-market pricing.

- Slow Manufacturing Speed (for whole shoes):

- While capable of fast prototyping, printing an entire shoe (if possible) or even a complex midsole can take hours.

- This is not comparable to traditional injection molding or compression molding. These processes can produce thousands of units in a single day.

- Result: Limits scalability for high-volume production.

- Limited Material Variety:

- Current 3D printing processes are generally restricted to specific types of polymers (e.g., certain resins, TPUs).

- Footwear requires a diverse range of materials—soft foams for cushioning, hard rubbers for outsoles, flexible fabrics for uppers, strong adhesives.

- Result: It's difficult to integrate all these properties into a single 3D-printed shoe efficiently. This means conventional components are still needed.

- Multi-Material Printing Challenges:

- Creating a multi-material shoe with varying densities, hardnesses, and colors in a single print run is technically complex. It is not yet widely available for footwear production.

- This means most "3D-printed shoes" still involve conventionally manufactured uppers and outsoles. Only the midsoles or other specific components are printed.

- Result: Hinders the vision of a truly "printed" shoe.

- Durability and Performance (Evolving):

- While individual components show promise, ensuring the long-term durability of a fully 3D-printed shoe, especially the connection points between different printed materials, is still an area of research.

- Concerns about "creep" (deformation under sustained load) in some printed polymers exist.

- Result: While improving, ongoing validation is crucial before widespread adoption across all performance categories.

- Size of Build Area:

- Even large industrial 3D printers have build envelopes. These constrain the size of objects that can be printed.

- Printing larger shoe sizes or multiple shoes simultaneously can be challenging on some machines.

These limitations are why 3D printing is currently a specialized tool in the footwear industry, primarily used for pushing design boundaries, offering customization, and for high-performance niche products.

Limitations of 3D-Printed Footwear (Current State)

| Limitation | Description | Impact on Mass Market Readiness | Current Mitigation / Future Outlook |

|---|---|---|---|

| High Production Cost | Expensive raw materials (resins), high machine costs, labor for post-processing. | Major Barrier: Makes price per pair prohibitive for most consumers. | Material and machine costs are slowly decreasing with scale; new processes. |

| Slow Manufacturing Speed | Printing entire shoes or complex midsoles takes hours per unit. | Limits Scale: Cannot compete with traditional high-volume production. | Faster printing technologies (e.g., DLS) are emerging for specific components. |

| Limited Material Variety | Restricted to specific printable polymers; lack of full range (e.g., soft foams, hard rubbers for soles). | Functionality Gap: Requires hybrid approach (printed component + traditional assembly). | Development of new printable materials and multi-material printing. |

| Multi-Material Printing | Challenging to print different materials (hardness, color) seamlessly in one go for a full shoe. | Design Compromise: Prevents fully integrated, printed shoes. | Active research area; specialized machines for multi-material parts are emerging. |

| Post-Processing | Many prints require washing, curing, sanding, or painting, adding time and labor. | Adds Cost & Time: Reduces efficiency of the printing process. | Improved resins/printers reducing post-processing needs. |

3D-printed shoes are rapidly advancing but are not yet ready for the mass market. The technology excels in creating customized, intricate components and prototypes, offering unparalleled design freedom. However, high costs, slow production speeds for entire shoes, and material limitations currently restrict its widespread adoption. Despite these challenges, continuous innovation promises a future where 3D printing plays an even larger, more integrated role in footwear manufacturing.